IMA SCREEN GP 5500

Button

IT HAS A SCREEN

GLOSSY VINYL PAINT GP 5500

INK TYPE

High-gloss, quick-drying vinyl paint, composed of pure, high-quality resins.

APPLICATION

In all plasticized and semi-plasticized vinyl materials. These inks are especially recommended for printing on self-adhesive vinyl. These paints also give very good results on rigid vinyl materials. With 5-10% of the solvent for styrene, GP paints have very good adhesion to polystyrene.

SOLVENT

Solvent GP 5500 Normal.

Quantity: approximately 10% depending on color.

DRYING

Physical drying by evaporation of solvents. The paint layer does not sweat or become sticky when stacked.

DRYING TIME

More or less an hour, depending on the level of humidity, ventilation and temperature. A high percentage of plasticizers in the vinyl material increases drying time. We recommend stacking only after 8 hours. To print very fine details, Universal Retarder (10-15%) can be added. When excess Retarder is added, the print quality does not decrease but the adhesion of the ink layer may decrease.

GRIP

Great. Solvents penetrate rigid vinyl with some difficulty, but there is a special solvent for this. It is recommended to use GP 5500 Solvent for Rigid PVC in this case. In plasticized vinyls, solvents penetrate more easily and deeper.

ELASTICITY

Very high, even greater elasticity than the material on which it is printed. The expansion or shrinkage of the material is perfectly monitored by the paint.

OPACITY

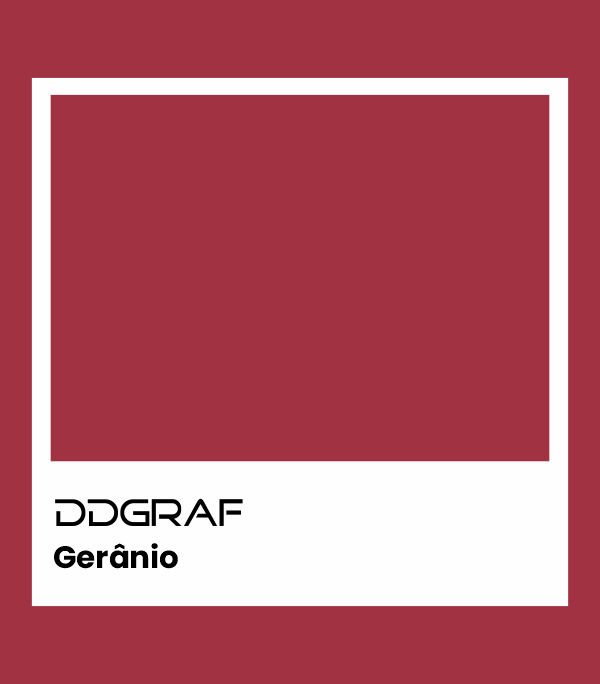

Very good for all colors. The opacity of Verde Paris GP 5513 and Gerânio GP 5509 is slightly lower than the other colors.

BLEEDING

A special property of GP inks is that they do not bleed, which means that when you print white on top of red the colors do not bleed, which is very important for preparing “double-sided” self-adhesive prints.

RESISTANCE

Great. GP paints are generally used with durable materials, and therefore the durability of the paints follows the durability of the material, even when exposed outdoors. Under normal conditions, these paints retain their quality for many years when exposed outdoors.

LIGHT RESISTANCE

The light resistance of pure colors is very high (several years). The thicker the paint layer, the greater the light resistance. When mixed with a very large amount of GP 5501 White or GP 5500 Varnish the light resistance decreases.

OBSERVATION

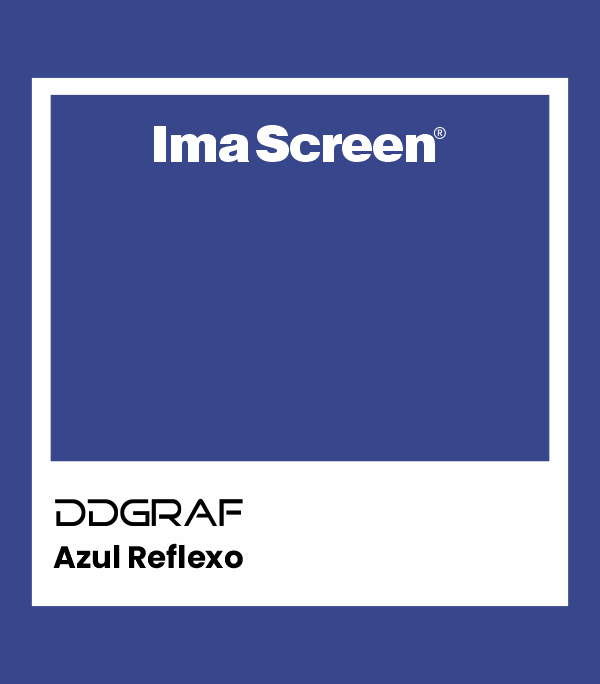

The color GP 5523 Blue Reflection is the only one that does not have good resistance to light or weather and, consequently, is not suitable for jobs that require these characteristics.

In general, it is not necessary to add a retarder to achieve very fine details. These are achieved very easily. GP inks do not block the screen and print without causing a “spider web” effect. Printed surfaces are completely smooth.

EXTENSION CAPACITY

Depending on the screen used: GP 5500 ink has the following yield:

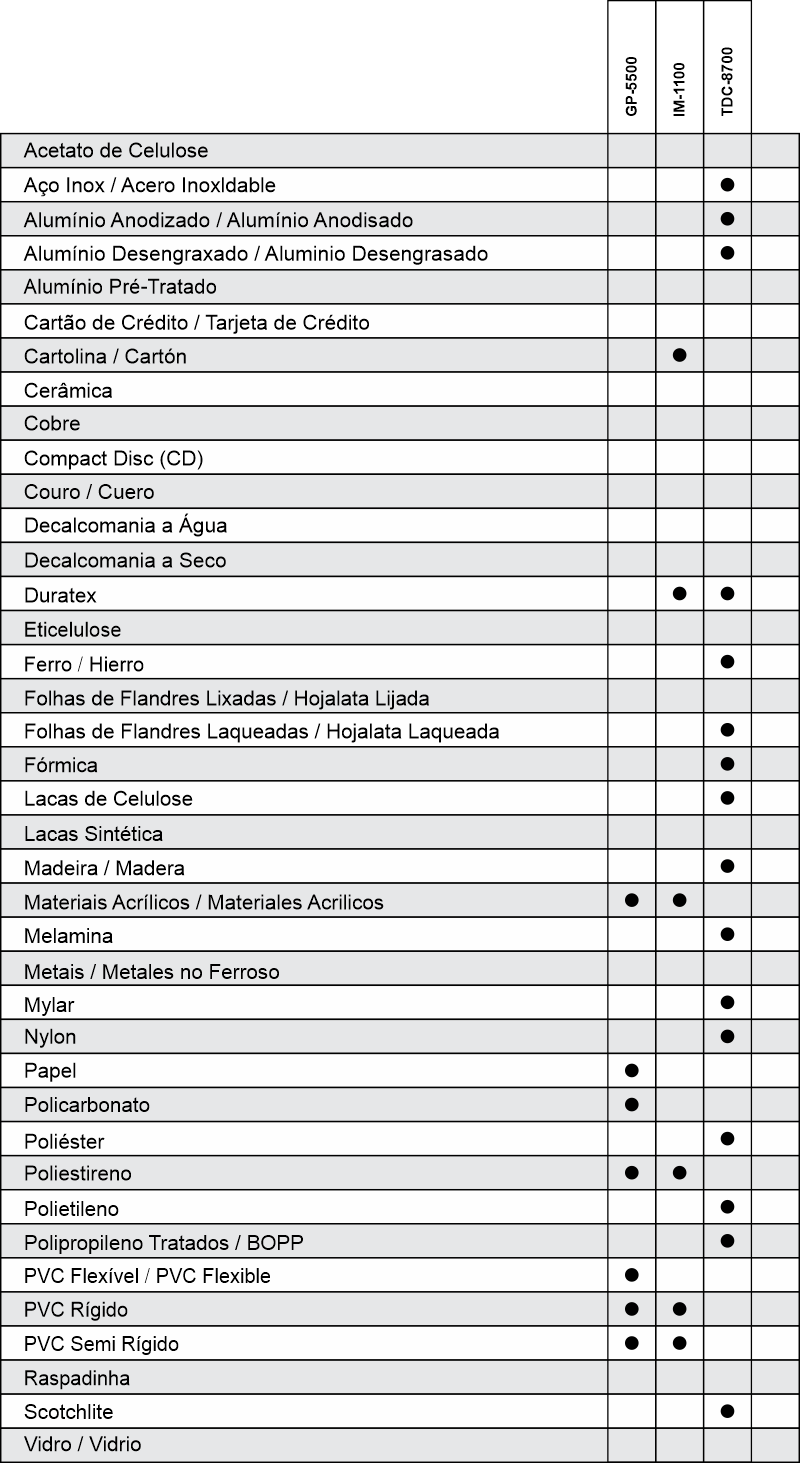

COMPATIBILITY

IMPORTANT:

All information contained herein is the result of our experience and provided in good faith. We suggest carrying out prior tests to prove the effectiveness of the product in relation to the desired results. If you have any questions or suggestions, please contact the Technical Department of Ddgraf Ind. E Comércio De Tintas Gráficas LTDA. REMEMBER: The use of all chemical products within environmental and safety standards shows respect for life.

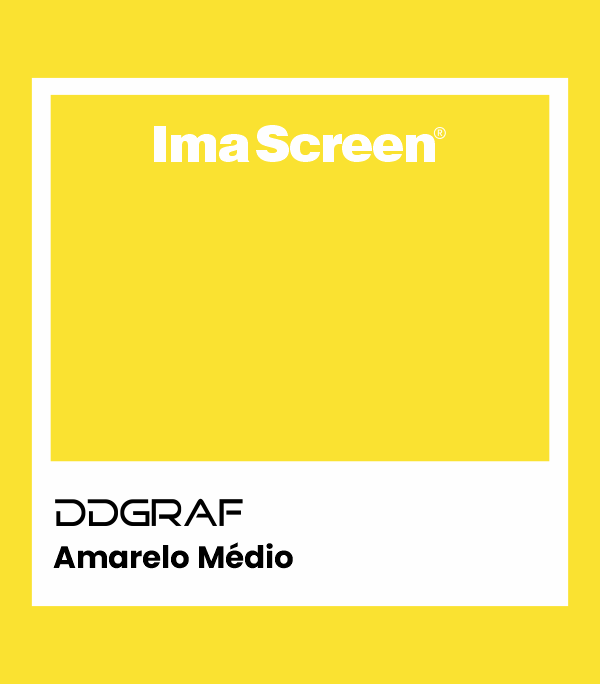

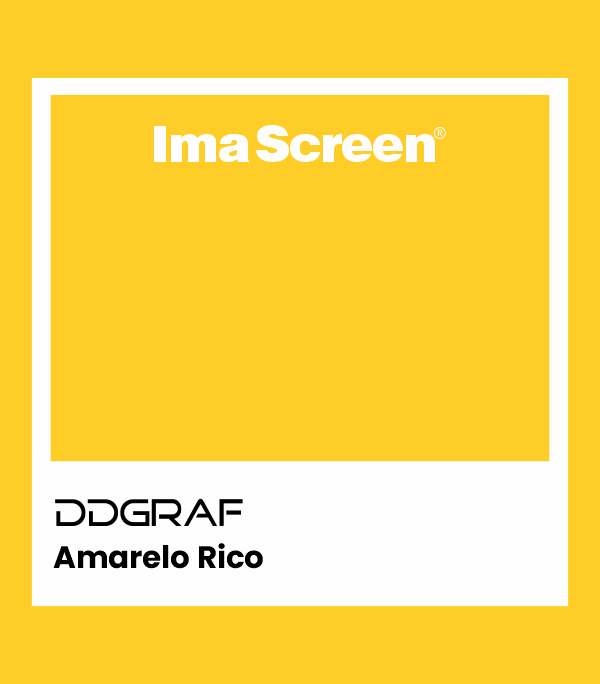

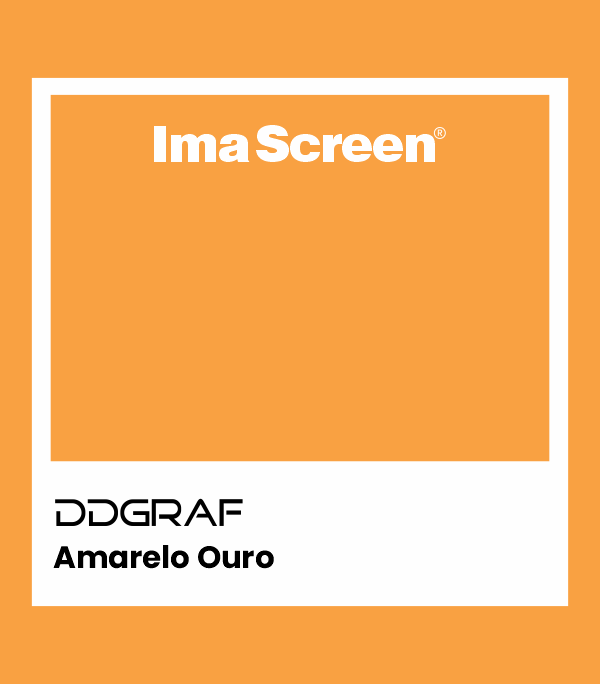

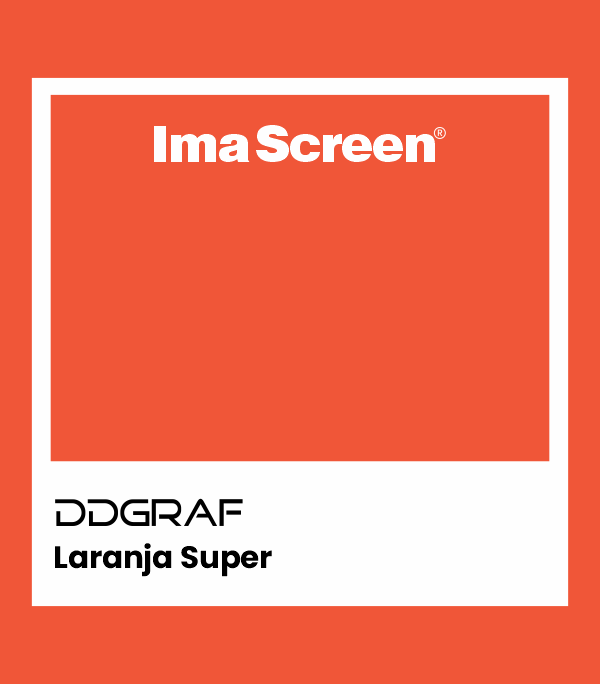

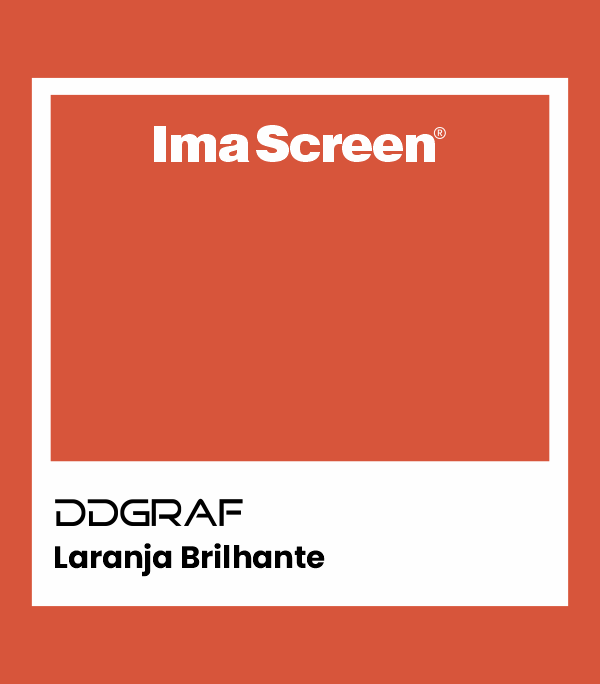

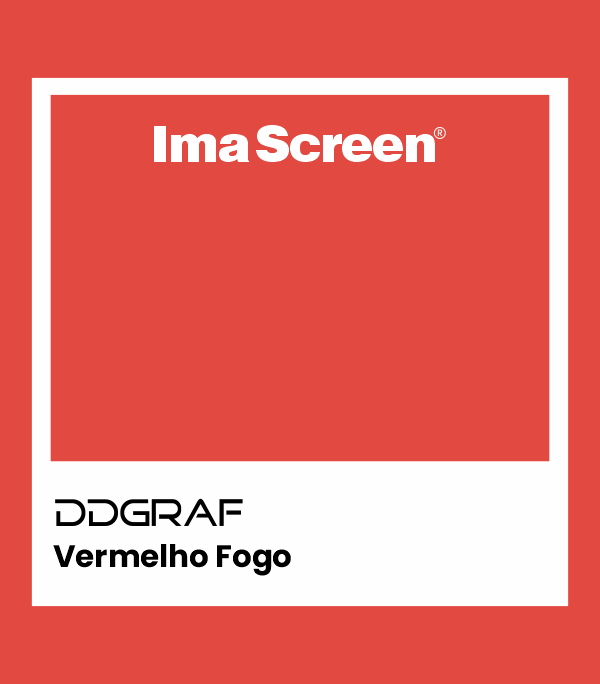

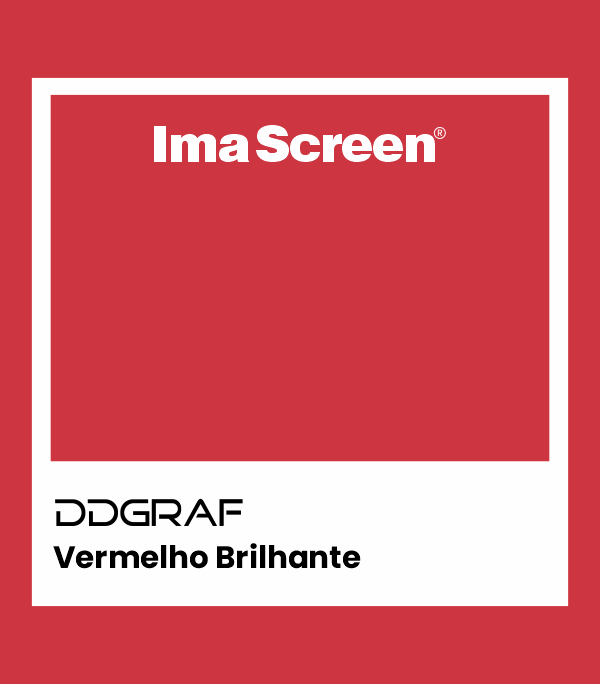

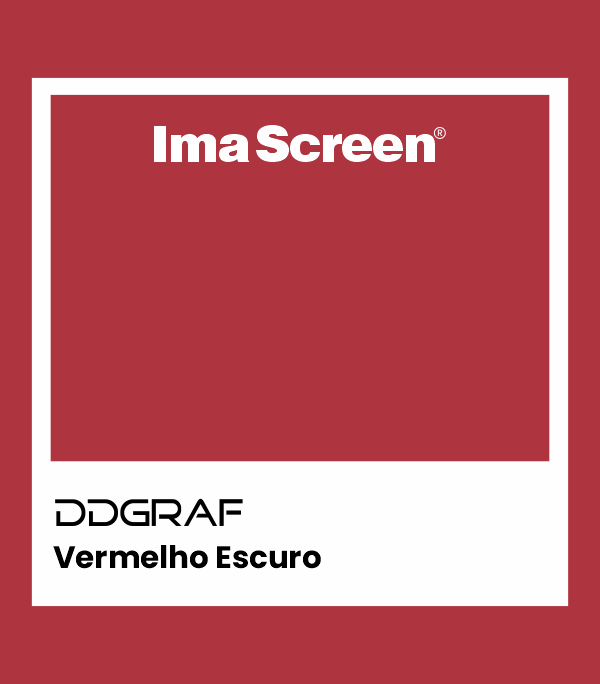

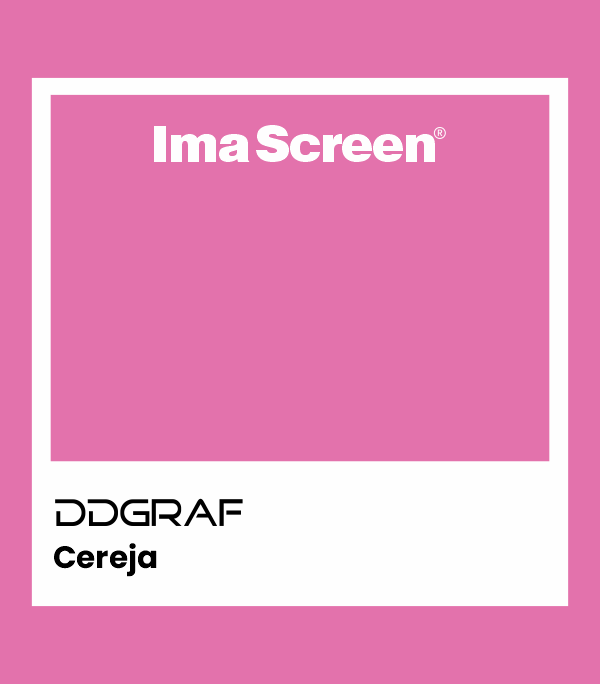

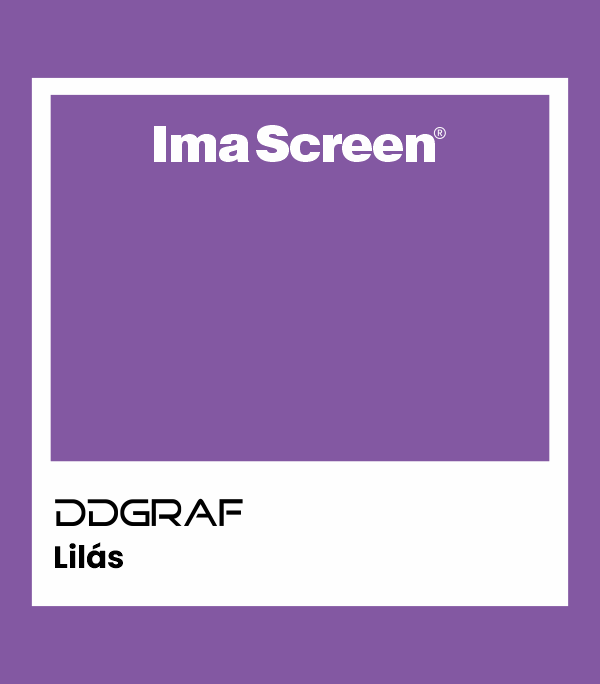

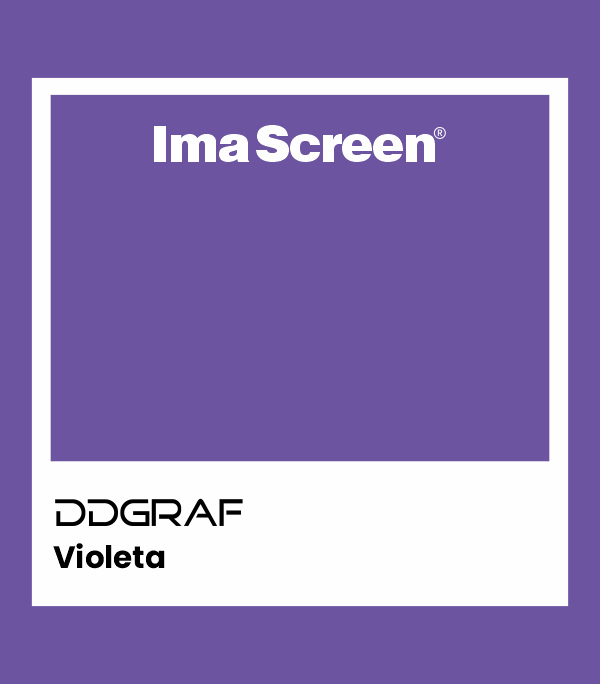

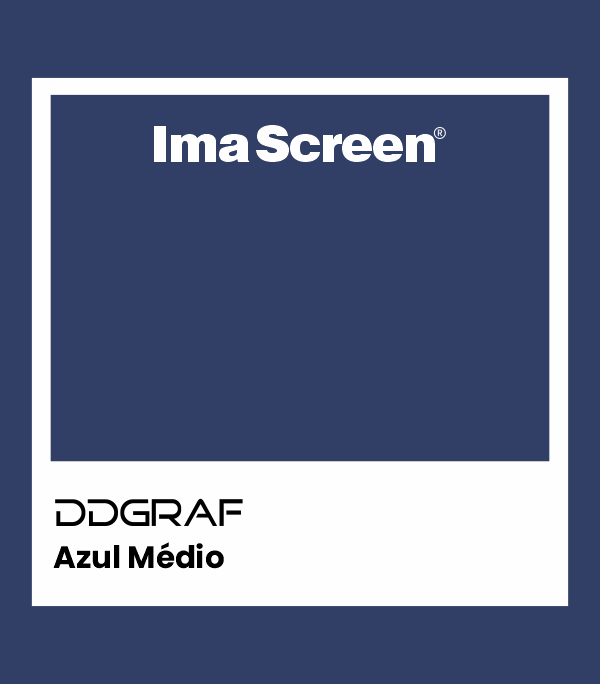

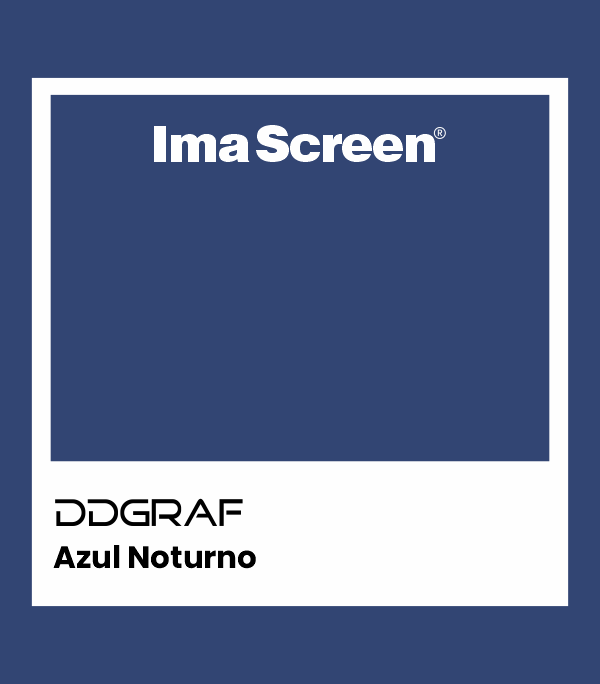

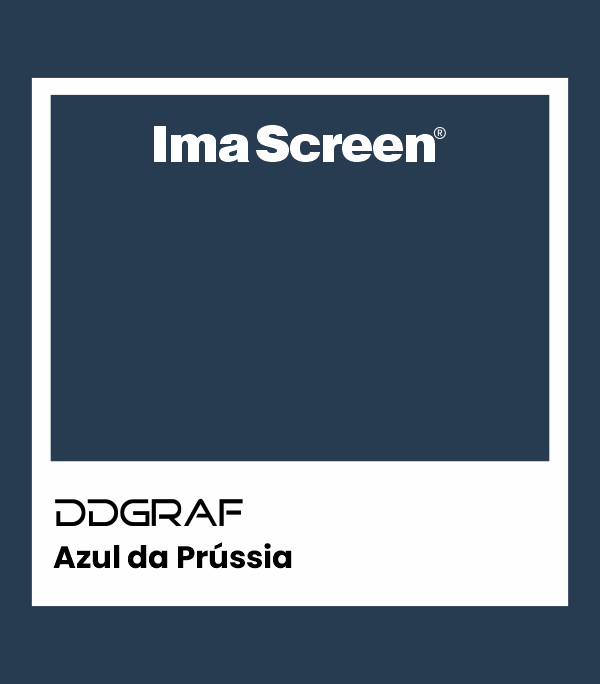

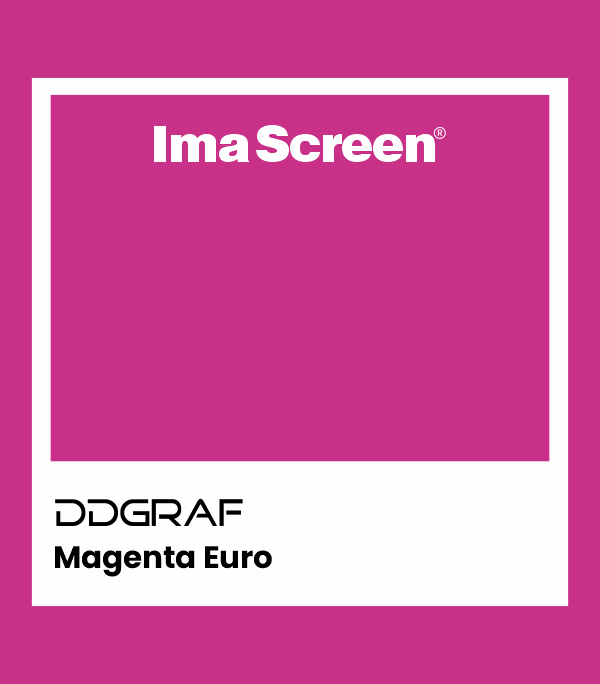

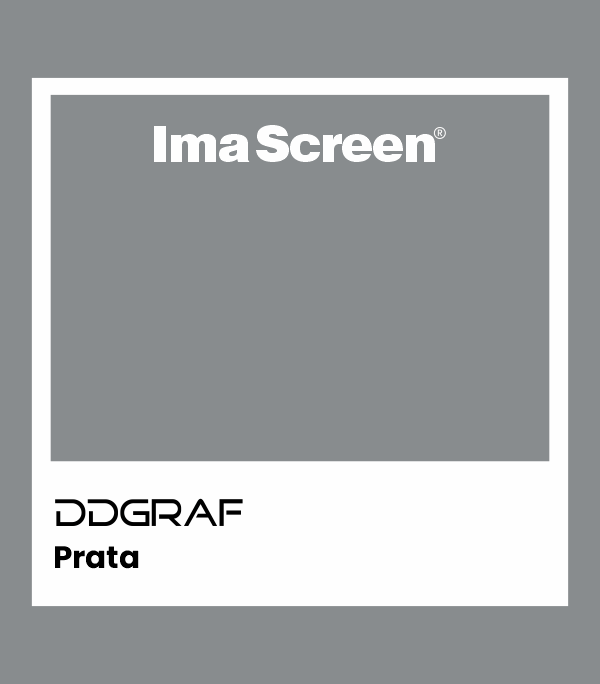

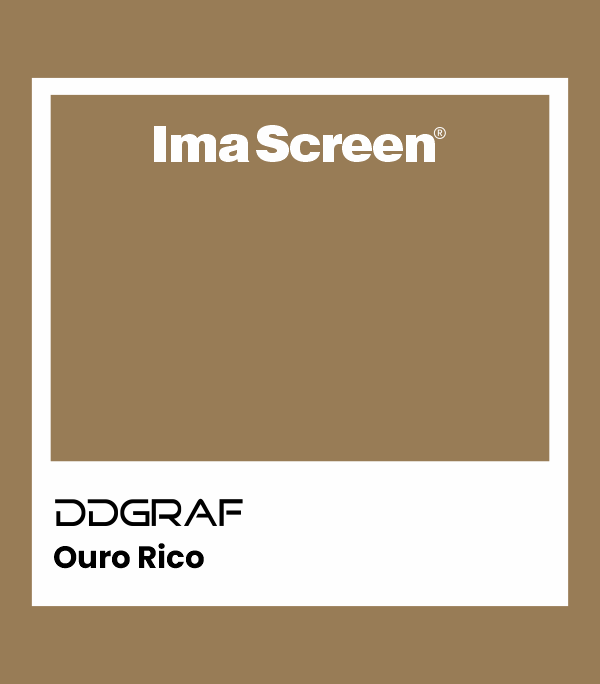

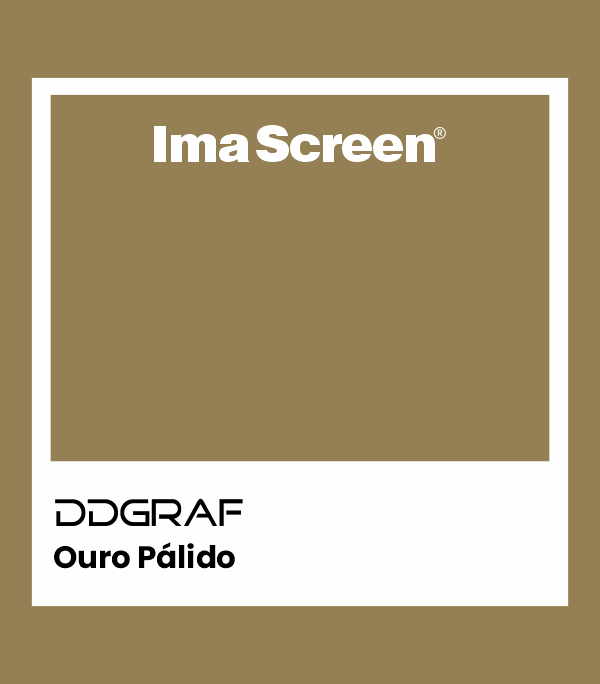

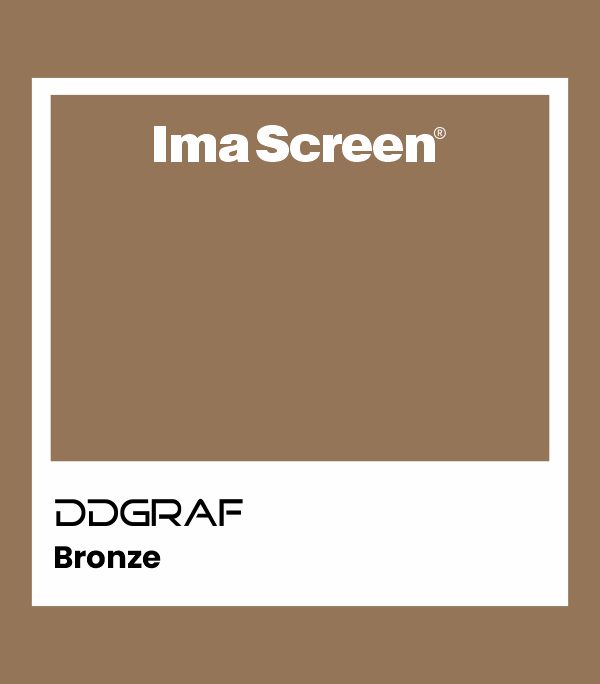

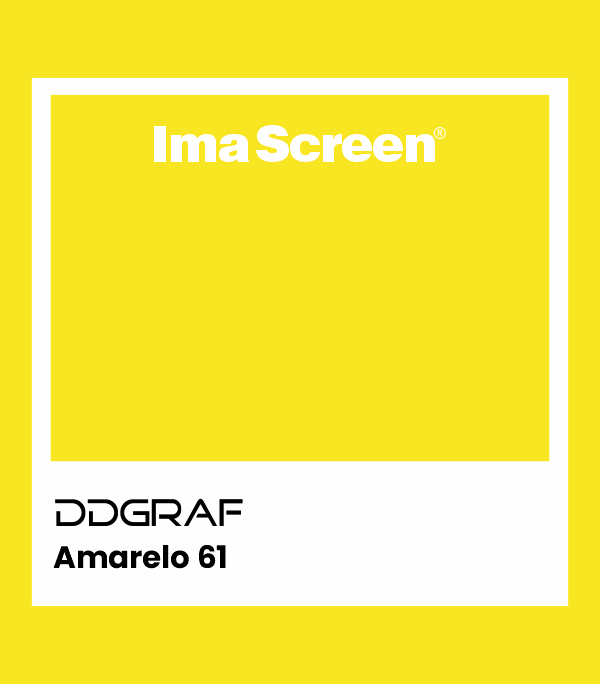

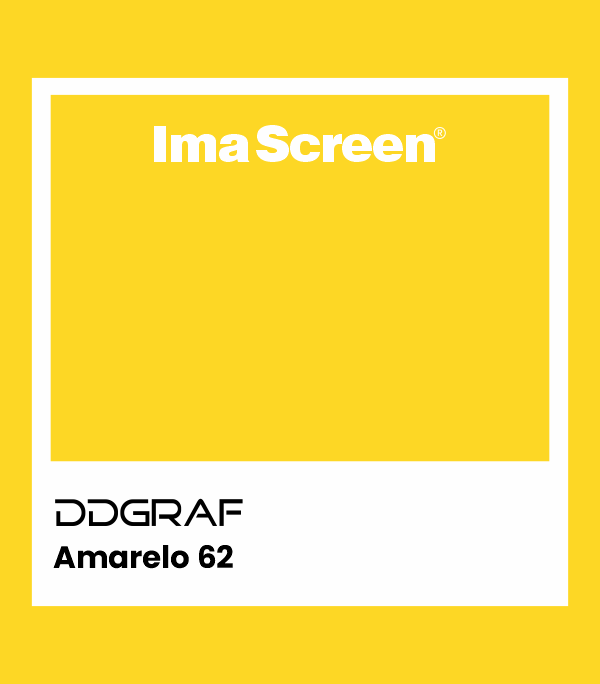

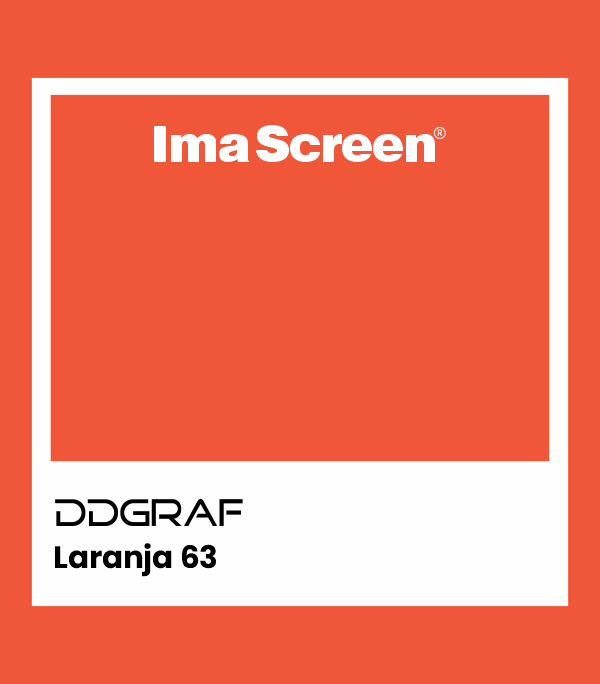

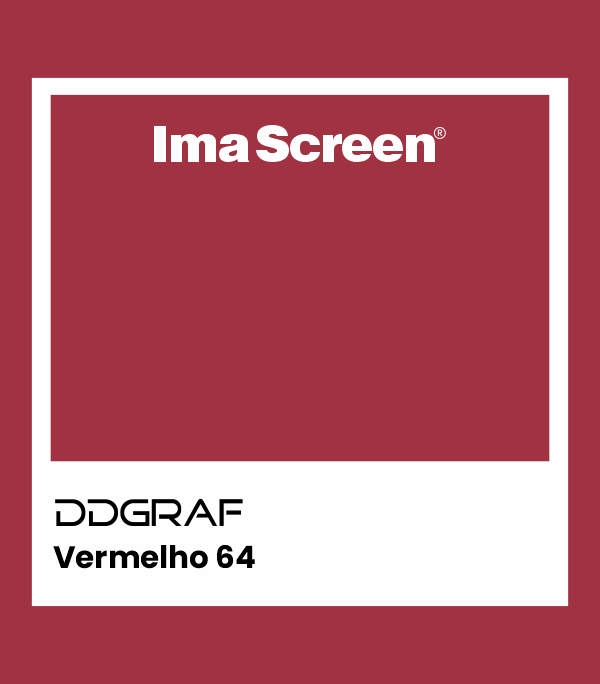

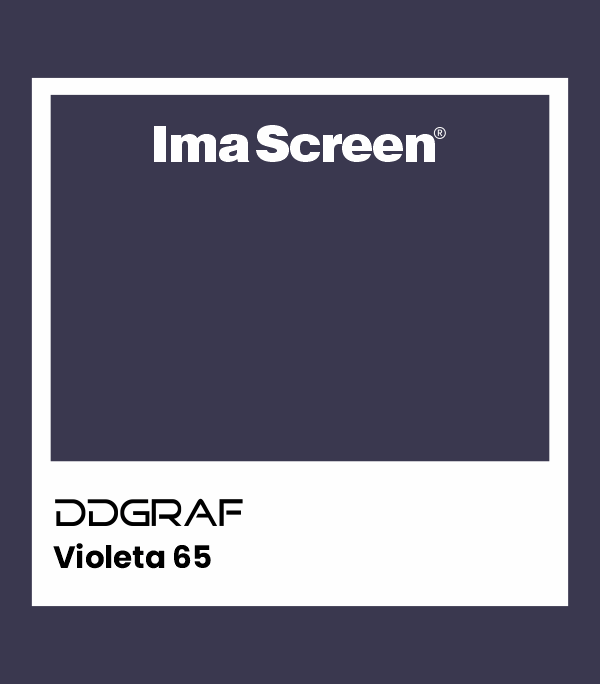

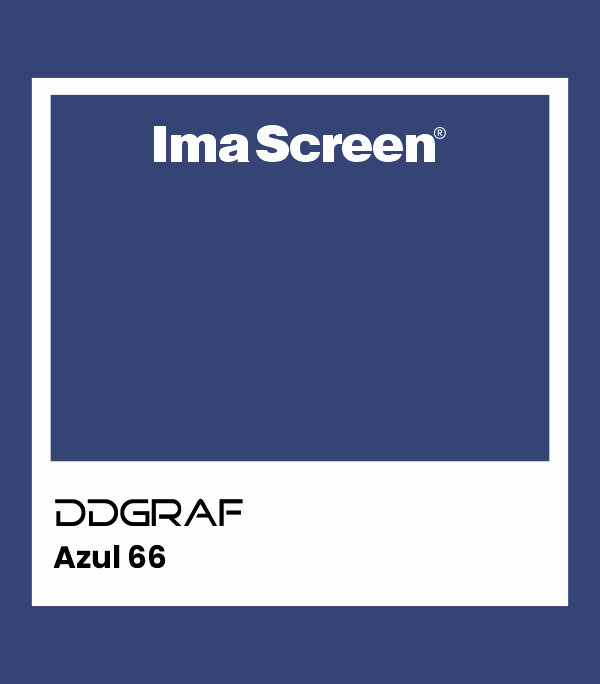

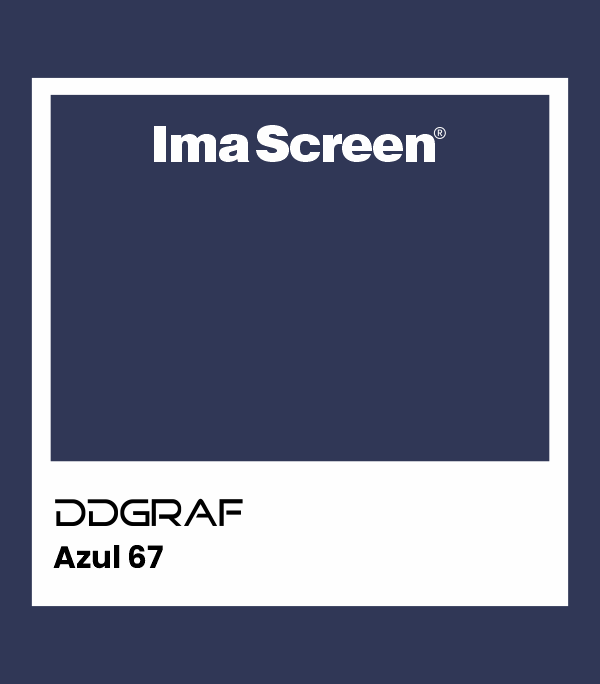

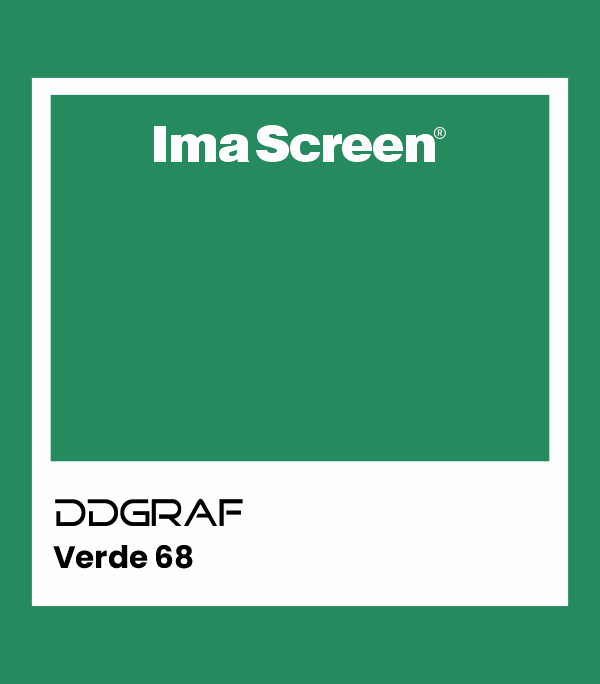

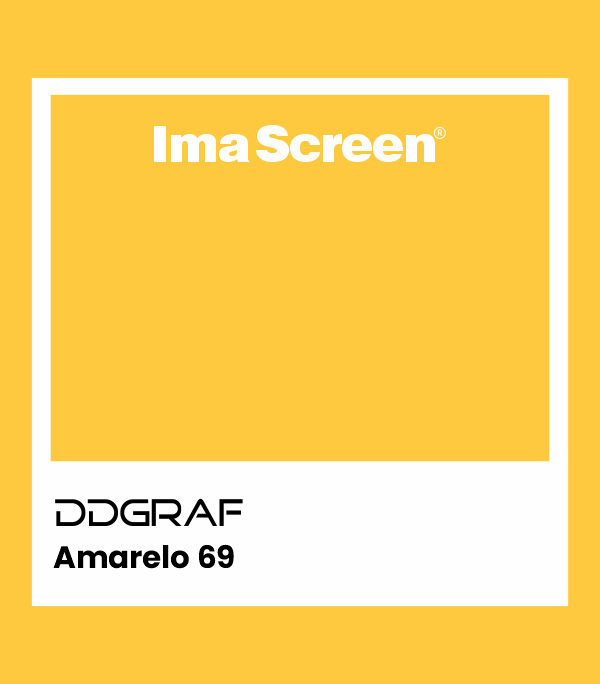

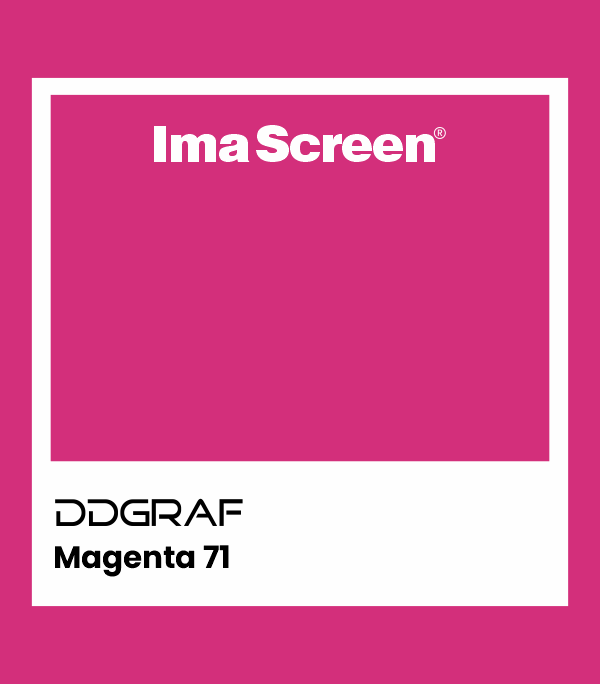

COLOR CHART

*** Product colors may vary depending on your monitor, please request a physical sample ***

FISPQ REQUEST - IMA SCREEN